PMT-18 HEAT TREATING KILN

Uses: Heat Treating - Industrial

THIS OVEN NOW SHIPS WITH THE SENTINEL TOUCH SCREEN CONTROLLER!

Solid Construction

The door swings open with one-handed operation. The PMT-18 furnace is insulated with refractory firebrick. The elements are mounted in dropped, recessed grooves machined into the firebrick. Paragon invented this type of groove in 1952. This groove protects the element for long life and low maintenance. Elements are simple to replace because they’re exposed rather than embedded. You can thread new elements into place following clear instructions in the manual.

The firing chamber is protected by a steel case painted in high temperature blue. A built-in stand lifts the firing chamber safely off your worktable, so no extra stand is needed. The door is mounted with a heavy-duty hinge for smooth opening.

A micro-switch shuts off the power to the elements when the door is opened. We use high temperature wire in the switch box for long life. A heat shield, mounted between the switch box and furnace, helps keep the switch box components cool even during extended operation. To further dissipate heat, the switch box is extra large and generously louvered. Each furnace comes with a cord and plug for immediate installation and a one year warranty.

Thermocouple with “special limit” wireThe thermocouple senses temperature inside the kiln. It is the small rod that extends into the firing chamber. The ¼” wide Type-K, 14-gauge, exposed-tip thermocouple is made with special-limit wire for superior accuracy. The exposed tip gives the controller a fast response time for even temperatures during holds. The thermocouple is made in America to our exacting standards. |

|

Designed for productionParagon’s warranty is not affected by frequency of use. Fire your new kiln every day if you want, even in commercial settings. That will have no effect on the warranty period. |

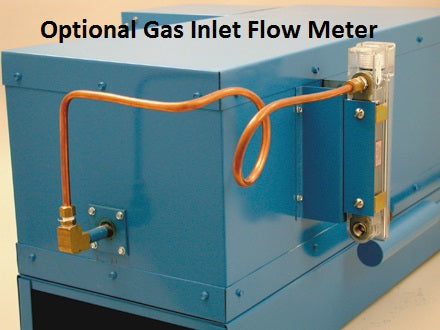

Optional Gas Injection Flow Meter

During heat treating, scale forms on the surface of the steel. One way to eliminate most scaling is to wrap the steel in stainless steel foil. An easier way is to install the gas injection flow meter on your furnace. It is available as either an add-on kit, or you can order the furnace with the meter installed.

The meter regulates the flow of an inert gas, such as argon, inside the furnace. The gas displaces the oxygen to prevent most scaling.

Please note that the gas may reduce heating element life. Also, gas injection does not offer better results than heat treating foil nor does gas injection prevent all scaling. The main benefit of gas injection is the savings in time over wrapping the steel in foil.

Please remember that results with the flow meter vary depending on the type of inert gas you use and your level of experience.

Specifications

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||