KM-45T Knife Making Kiln

Uses: Knife Making

THIS KILN NOW SHIPS WITH THE SENTINEL TOUCH SCREEN CONTROLLER INSTALLED!

The KM-45T is insanely large! With an interior depth of 45", this kiln will handle any project a knife maker can dream up.

Long lasting solid state relay

The KM45T now has a solid state relay, which lasts far longer than a standard mechanical relay. The solid state relay has no moving parts to wear out. The first thing you will notice is that the solid state relay is silent. You will hear just the reassuring hum of elements. The solid state relay makes heating elements last longer and offers better temperature control during holds.

Choose a side swing door or a drop door

You can order a Paragon knifemaking furnace with either a drop door or a side-swing door. The price of the furnace is the same with either door style.

The drop door opens downward with one-handed operation. A counter-weight handle holds the door securely closed. The door, whether drop or side-swing, is mounted on a heavy-duty 1/2” thick hinge shaft for smooth opening. Because of the rigid case and heavy hinge, the door is sturdy enough for years of faithful service.

Door safety switch

The door micro safety switch shuts off the power to the elements when the door is opened, yet the controller continues to give a temperature readout. The safety switch is standard on Paragon KM furnaces.

Test exotic heat treating formulas

When you own a Paragon KM-45T furnace, you can live the knife making adventure to the fullest. You will actually witness the birth of your knives, for the soul of the blade is born in the crucible of the furnace.

There are many reasons to own a furnace. For instance, you can test and refine heat treating formulas. Each time you alter the heat treatment, test how many times a new blade can cut hemp rope and 2x4s. Can the blade bend to 45° or even 90°? After you run the blade through the first tests, take it out into the real world on a camping trip and test it further.

The knife maker with a KM-series furnace can try exotic heat treating methods at his leisure. Does quenching in dry ice improve blade performance? What happens when 52100 ball bearing steel is triple-quenched? Does a one-day wait between each quench matter? After this treatment, will the blade bend to 90° without chipping?

With a Paragon furnace in your shop, all questions about heat treating formulas are settled.

Solid furnace construction

The furnace is insulated with 3” thick refractory firebrick, which is 1/2” thicker than the standard. The elements are mounted in dropped, recessed grooves machined into the firebrick. This groove protects the element for long life and low maintenance. Elements are simple to replace because they can be lifted directly from the groove. You can replace elements following instructions in the printed manual. The firing chamber is protected by a rigid steel case. A built-in solid stand lifts the firing chamber safely off your worktable. The thermocouple wire is kept inside the control box for protection from the harsh environment of the typical bladesmith shop.

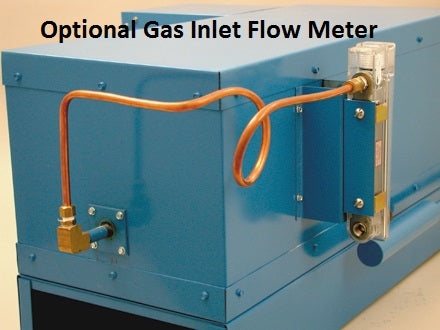

Optional gas injection flow meter

During heat treating, scale forms on the steel. You can eliminate most scaling by wrapping the blades in stainless steel foil. Or you can install the gas injection flow meter on your furnace. It is available as either an add-on kit, or you can order the furnace with the meter installed. The meter regulates the flow of an inert gas, such as argon, inside the furnace. The gas displaces the oxygen to prevent some of the scaling. For more details, click on the link in the Options section below.

The knifemaking kit

In addition to the furnace, you will need a knifemaking kit, which separates the blades and holds them parallel inside the furnace. Please click the link below in the Options section.

Thermocouple with “special limit” wireThe thermocouple senses temperature inside the kiln. It is the small rod that extends into the firing chamber. The ¼” wide Type-K, 14-gauge, exposed-tip thermocouple is made with special-limit wire for superior accuracy. The exposed tip gives the controller a fast response time for even temperatures during holds. The thermocouple is made in America to our exacting standards. |

|

Designed for productionParagon’s warranty is not affected by frequency of use. Fire your new kiln every day if you want, even in commercial settings. That will have no effect on the warranty period. |

|

Optional colors at no extra chargeBrighten your studio with color! Order your kiln in one of our standard colors at no extra charge . . . berry, black, blue, hot pink, jade, navy, purple, or turquoise. |

Specifications

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||